The term originally referred exclusively to the treatment of natural rubber with sulfur which remains the most common practice.

Characteristics of vulcanised rubber.

As players increase their archaeology level and use higher tier mattocks they are able to excavate vulcanised rubber at quicker rates.

It is made from various types of raw rubber including organosilicon ethylene propylene and isoprene raw rubber which are filled with white mineral fillers.

Dielectric cable vulcanized rubber is characterized by small dielectric losses and high electric strength.

The vir cables were used in the majority of the wiring in properties and on the whole did not have an earth wire attached the continuous protective circuit.

Vulcanization can therefore be defined as the curing of elastomers.

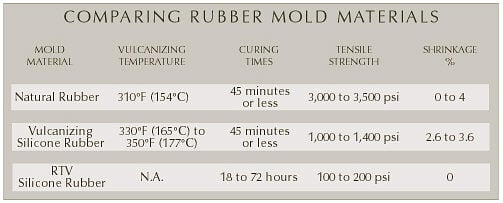

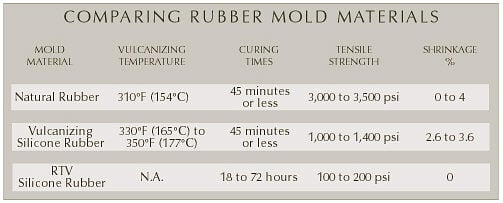

Tensile strength is maximum at optimum cure.

By vulcanising rubber in moulds products of rather intricate shape can be obtained.

However it has also grown to include the hardening of other rubbers via various means.

In its simplest form vulcanization is brought about by heating rubber with sulfur.

Nr is stabilized by vulcanizing it using sulphur.

Vulcanized rubber is a thermoset plastic because once molded vulcanized rubber retains its shape and cannot be reformed.

Physical properties can be varied over a wide range of rigidity and flexibility.

Structure of the rubber.

Vulcanized rubber has an intermolecular system with highly cross linked polymer chains.

With the terms vulcanization and cu.

What is vulcanization of rubber how to vulcanize rubber the process transforms elastomers with weak thermoplastic properties into a strong elastic and tough substance with useful properties and introduces a network of cross links into the elastomers.

High strength elasticity durability and waterproofness which are granted through a chemical process.

Examples include silicone rubber via room temperature vulcanizing and chloroprene rubber using metal oxides.

Rubber insulation and other rubber products require shaping prior to vulcanisation because the vulcanised rubber cannot be shaped by mechanical pressing once it has acquired its characteristic plasticity.

Vulcanised rubber is required to restore various artefacts.

This process vulcanization takes place when rubber is heated with a curing ingredient typically sulfur.

Vulcanized rubber is marked by a few key characteristics.

Unvulcanized rubber only has polymer chains doesn t have cross links or intermolecular networks.

Finished rubber has higher tensile strength and resistance to swelling and abrasion and is elastic over a greater range of temperatures.

It is used in almost pure form dip or mixed with other materials.

Vulcanization chemical process by which the physical properties of natural or synthetic rubber are improved.

The process is carried out by heating the rubber mixed with a vulcanizing agent in a mold under pressure.

Vulcanization refers to a range of processes for hardening rubbers.