An aluminum alloy is a chemical composition where other elements are added to pure aluminum in order to enhance its properties primarily to increase its strength.

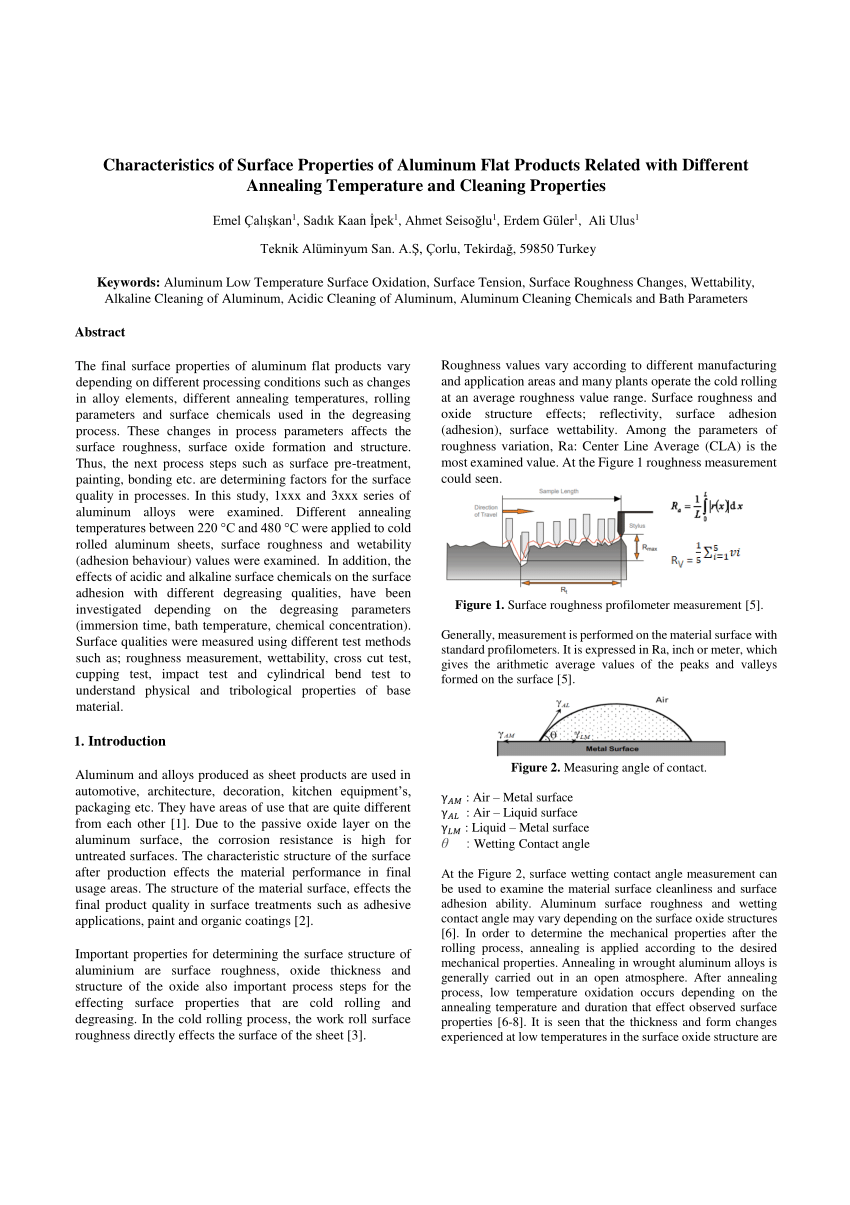

Changes in aluminum sheet characteristics.

It has a boiling and melting point of 660 c 1220 f and 2 327 2 450 c 4 221 4 442 f respectively.

Visual quality characteristics of aluminum sheet and plate has been compiled by the technology committee of the sheet and plate division as a reference for those who have an interest in these rolled products and who may have a need to know the terminology commonly used in this largest segment of the alu minum industry.

In the experiment we used an aluminum sheet with a thickness of 0 5 mm to form the stack and we sandwiched the composite panel between the aluminum sheets.

Examples of chemical changes are burning cooking rusting and rotting.

These other elements include iron silicon copper magnesium manganese and zinc at levels that combined may make up as much as 15 percent of the alloy by weight.

Aluminum alloys have been the dominant materials used for airframe structures until the increasing trend in the use of polymer matrix composites as shown in table 4 1 1 2 the boeing 787 and airbus a350 are built with about 50 of these materials which are lighter than aluminum alloys and possess better resistance to degradation by corrosion and fatigue.

Aluminium aluminum in american and canadian english is a chemical element with the symbol al and atomic number 13.

Ical properties of the original components are diminished or nonexistent.

The physical properties of several typical aluminum alloys and a widely used structural steel are illustrated in table 1 2 ref 1 2 1 7.

Examples of physical changes are boiling melting freezing and shredding.

Aluminum is a silvery metal with a slightly bluish tone.

It is the maximum stress that the cross section is subjected to when the load is applied between the two points of the specimen.

It is the maximum stress that the sheet metal material is subjected to before pulling out.

Often physical changes can be undone if energy is input.

More com table 1 2 physical properties of representative aluminum alloys and steel m aterial m eltin rane b oilin p oint.

Its density is 2 708 grams per cubic centimeter.

When the bend radius in sheet metal options is set to thickness ratio and you change the sheet metal part thickness for the part the value for the inner radius now changes in the properties panel.

13 4 shows the effect of the thickness of glass fiber composite panel on the required load i e maximum value required for a complete punching operation.

The sample used was made.

N mm2 or mpa the symbol is σb.

It is one of the indexes of metal strength.